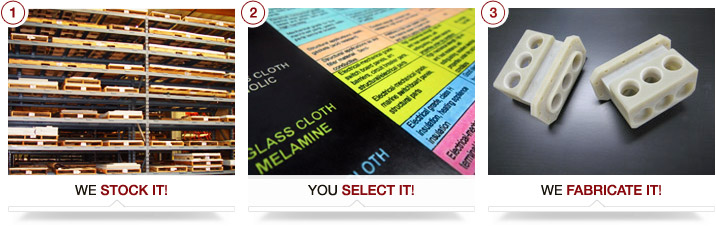

Plastic Fabricating Laminate Machining

Close Tolerance Thermoplastic Machining

Vanderveer Industrial Plastics deals with thermoplastics and thermoset composites and laminates in various grades.

All plastics are viscoelastic, which translated means that the stiffness of the material will depend upon how long that said material is under load.

Close Tolerance Thermoplastic Machining materials offered:

- Micarta G10/FR4

- ABS

- Acetal

- Acrylic

- Delrin

- Nylon

- Nylatron

- PEEK

- Plexiglass

- Polycarbonate

- Polyethylene L/D - H/D

- Polypropylene

- PVC

- Ryton

- Rulon

- Teflon PTFE/FEP

- Torlon

- Ultem

- UHMW

- Vespel

Thermosetting vs. Thermoplastic

Thermoplastics, also known as thermo-softening plastics, consist of a polymer that becomes pliable or moldable beyond a certain temperature, and then returns to a solid state upon cooling. Examples include polyethylene, polypropylene, polystyrene, polyvinyl chloride, and polytetrafluoroethylene (PTFE).

Thermoset plastics differ in that they remain in a constant solid state regardless of temperature.

Occasionally, we might refer to a NEMA grade. NEMA is the regulating authority for insulating laminate grades and stands for National Electrical Manufacturers Association. They are responsible for publishing more than 500 standards, application guides, technical papers, and white papers.

Grade designations for glass epoxy laminates that Vanderveer Industrial Plastics deals in are: G10, G11, and FR4. Of these, FR4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4's self-extinguishing flammability characteristics and for all intents and purposes is distributed by Vanderveer Industrial Plastics as G10/FR4.

Selection & Application Guide - Thermoplastics

Selection & Application Guide - Thermoset

Additional data sheets available upon request.

Click here to submit a Request for Quote

Or call us today at 714.579.7700