UHMW Machining

What is UHMW plastic?

UHMW is ultra-high molecular weight (UHMW) polyethylene bar with excellent high abrasion and impact resistance properties. UHMW is a high crystalline, high-density polyethylene polymer with a median molecular weight that falls within the range of 3.1 to 5.0 million. UHMW machined parts will outwear all other materials like metals, nylons, or fluoroplastics. This plastic has the same qualities of other polyethylene plastics. Since the UHMW material resists wear, corrosion, and friction, it allows for an extended equipment life and can cut maintenance costs. There are a variety of UHMW applications, including gears, rollers, wear plates, bearings, and more.

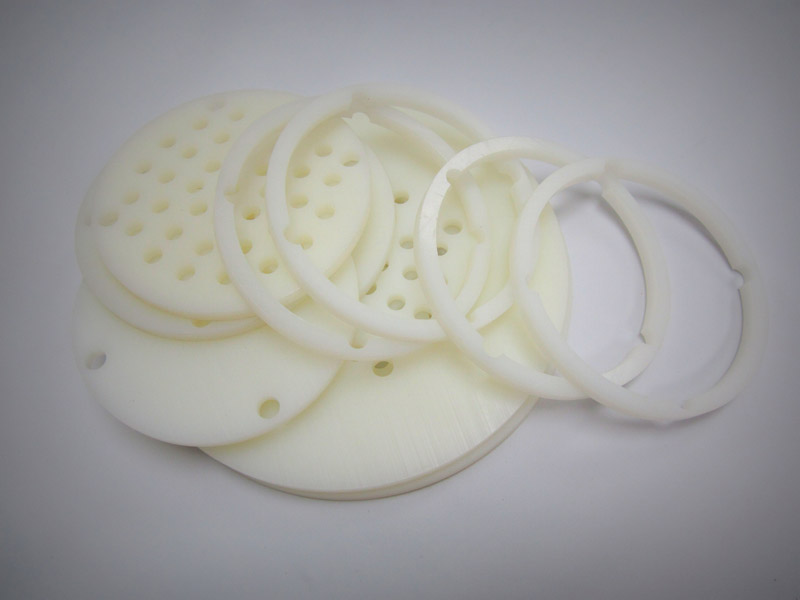

UHMW Machined Parts

Parts machined from UHMW polyethylene showcase an exceptional combination of outstanding properties. High abrasion resistance, low coefficient of friction, self-lubrication, non-adherent surface, excellent chemical fatigue, impact resistance, ease of machinability, and good noise-dampening properties are all inclusive of UHMW. Its outstanding characteristics embrace high wear and abrasion resistance and high performance at extraordinarily low temperatures (i.e., liquid nitrogen -259 degrees C). Only when temperatures reach 185 degrees F, will UHMW start to soften and lose its abrasion resistance characteristics.

Because UHMW features a comparatively high expansion and contraction rate once subjected to temperature changes, it's not suggested for close tolerance applications in these environments.

However, custom UHMW machining to close fabrication tolerances is easily achieved through Vanderveer Industrial Plastics' CNC machining abilities.

UHMW Plastic Machining Profile:

UHMW Benefits:

- High impact strength

- Machinability

- Low coefficient of friction

- Self-lubricating

- Chemical resistant

- Zero water absorption

- High abrasion resistance

UHMW Applications:

Vanderveer Plastics fabricates custom UHMW machined parts for various applications that are extremely wear resistant. Some common applications include:

- Starwheels

- Chemical Tanks

- Fiber Applications

- Water Pipe Flanges

- Guide Rails

- Bushings

- Wear plates

- Bearings

- Bumpers

- Chain Guides

- Wear Strips

- Sprockets

Common UHMW Industries:

There are a variety of industries that utilize UHMW for their equipment because of its wear, corrosion, and friction resistance. Some industries include:

- Food Processing

- Material Handling and Packaging

- Conveyor Systems

- Marine

- Waste Water Treatment Facilities

Use Our Comparison Tool to Compare Materials

Common Comparisons

- Acetal vs. UHMW

- Delrin® vs. UHMW

- HDPE vs. UHMW

- Nylon vs. UHMW

- Polypropylene vs. UHMW

- Teflon® PTFE/FEP vs. UHMW

More Comparisons

More Comparisons:

- ABS vs. UHMW

- Acrylic vs. UHMW

- FR-4 vs. UHMW

- FR-5 vs. UHMW

- G-9 vs. UHMW

- G-10 vs. UHMW

- G-11 vs. UHMW

- G-3 vs. UHMW

- G-5 vs. UHMW

- G-7 vs. UHMW

- Grade C Canvas vs. UHMW

- Grade CE Canvas vs. UHMW

- Grade L Linen vs. UHMW

- Grade LE Linen vs. UHMW

- Grade X Paper vs. UHMW

- Grade XX Paper vs. UHMW

- Grade XXX Paper vs. UHMW

- Nylatron® vs. UHMW

- PEEK vs. UHMW

- Plexiglas vs. UHMW

- Polycarbonate vs. UHMW

- LDPE vs. UHMW

- PVC vs. UHMW

- Rulon® vs. UHMW

- Ryton vs. UHMW

- Torlon® vs. UHMW

- UHMW vs. Ultem®

- UHMW vs. Vespel®

For additional information on UHMW plastic materials, contact your local Vanderveer Industrial Plastics representative or call Vanderveer Industrial Plastics at 714.579.7700.

Click here to submit a Request for Quote

Or call us today at 714.579.7700