Nylatron vs. Teflon PTFE/FEP Machining

Comparison of Nylatron and Teflon PTFE/FEP Property Values

| Extruded Nylon | Cast Nylon |

|---|

| 1.2 | 0.6 - .12 |

| 12,400 | 10,000 - 13,500 |

| 410,000 | 420,000 - 500,000 |

| 4.5 | 5 |

| -- | -- |

| Material |

|---|

| Water Absorption Rating |

| Tensile Strength |

| Flexural Modulus |

| Coefficient of Linear Thermal Expansion |

| Dielectric Strength |

| Unfilled | 35% Glass Filled | 24% Carbon Filled |

|---|

| < 0.01 | 0.02 | 0.05 |

| 3,900 | 2,100 | 1,900 |

| 72,000 | 190,000 | 160,000 |

| 7.5 | 6.4 | 6.0 |

| -- | -- | -- |

- Metals Processing

- Pulp and Paper

- Marine

- Valves

- Pumps

- Textiles

- Food Processing

- Bearings

|

- Metal Forming

- Mining Equipment

- Material Handling

- Bottling Equipment

- Oil Field Applications

- Packaging Equipment

- Wear Strips

|

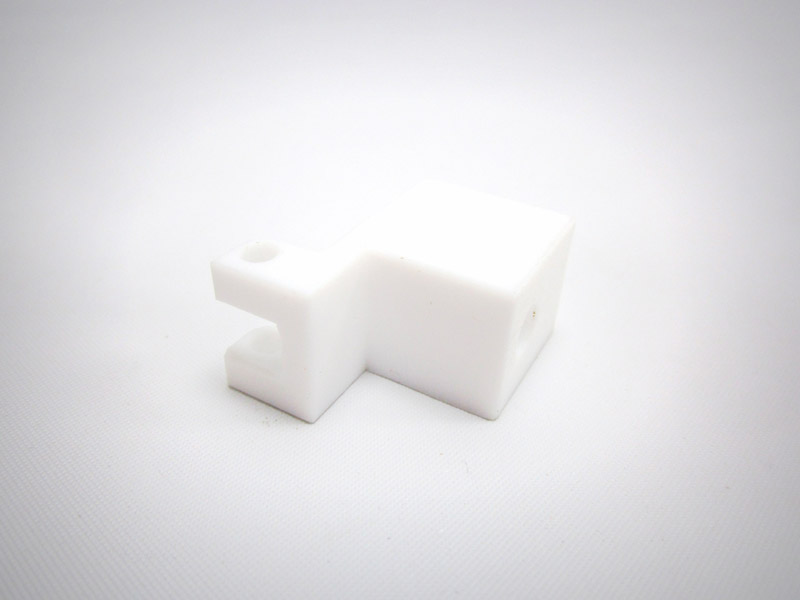

Material Properties

- Excellent wear resistance

- High mechanical strength

- Machinability

- Excellent dielectric properties

- Inertness to most chemicals

- High heat and chemical resistance

- Very low coeffiecient of friction

- Excellent radiation resistance

- Zero moisture absorption

- Relatively insensitive to power frequency

- Machinability

Click here to submit a Request for Quote

Or call us today at 714.579.7700